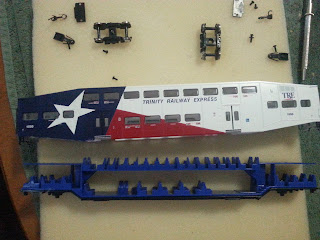

I have a passenger train called the TRE, or Trinity Railway Express. It is a commuter line that runs between downtown Fort Worth and downtown Dallas through the Trinity River basin. As a Texas boy I love the scheme so I've been working on making the model really awesome. I will detail the models in a later post. For me, the best thing to do to the cars is to add passengers and lights! Can't usually see the passengers without lighting... Not much gets through the thick plastic windows.

So the first thing that is needed for lighting passenger cars is the power source. Some cars use batteries and some use track power, along with a few other ideas. The best one is entirely up to the installer/user so examine the options and decide which you prefer.

In my case, I chose track power. It has a few advantages over battery power: no need to replace the battery, no battery to hide, lights will always be the same brightness, etc, etc. A downside is having to wire up the car to get power from the tracks.

The next step is to determine if there is the right equipment and room. Some coaches may require more planning and test fitting of components than others. Fortunately the coaches I have came with metal wheelsets and there are spaces on either end for the lighting circuit (above the seating on the single level areas). This was determined by taking the car apart and test fitting the equipment.

As seen in the picture of the trucks above, there is a gap between the frame and the wheels. This is where I put the pickup wires. I took the wire from burned out Athearn bulbs and made a simple loop around each wheel (the wheels are all individual, held together by the black plastic sleeve. I can explain other ways to do this wiring if you have different wheelsets). Below is the wired up truck. It took several tries to get this right. Basically the wire sits on the axle without being too tight and restricting turning, but is tight enough to provide constant contact.

Now the wires need a place to go. I used my Dremel and vertical stand to drill a holes through the bottom of the frame. It is the hole between the coupler screw and the truck mounting hole. There is an identical one on the other end. The wires go up and into the car where I used instant glue to guide them up the stairwell to above the circuit area.

Below is the lighting circuit completed. I found the plans for this circuit in Model Railroader. I do not remember the month unfortunately... Anyways, the author was using it to provide lighting in his buildings using the track bus wires. Fortunately it works just a well for lighting rolling stock!

Its consists of a small piece of wafer board, a 4700 Ohm resistor (I used a 1/4 Watt), a 220 microfarad capacitor (25 Volts or higher works perfectly), and a 1 Amp bridge rectifier (DF005M on Jameco Electronics website). These are important to use. The lights are DC powered so the AC powered track would blow them straight out. The bridge rectifier converts the AC power to DC power, so now any lights can be used! The resistor drops the voltage from about 12V (from the DCC system) to the ~3V of the lights. The capacitor keeps the lights from flickering across dirty track or powerless switch frogs.

These pictures show how it is wired (front and back). The AC power from the tracks goes to the ~ symbols, the positive output to the resistor, then to the lights. The negative output goes to the lights. The capacitor bridges the two outputs.

Now the wires are run to the lights.

The lights are these seen here at MicroMark. They are cheaper on eBay but take a very long time to arrive. Basically they can be cut to the necessary length then stuck in place. Fortunately for me, a strip of 3 and a strip of 9 fits perfectly. I soldered the lights up to each other and the circuit.

Lastly, I ran them through the car, attached them in the desired location and secured the circuit. I also put a few drops of instant glue in to control the wires and ensure the lights stay. Incredibly simple!

To finish it up, I tested the lights out then reassembled the car! Oh, and I put in some passengers. Below are shots of the lighting on and the lighting off.

And that's it! I spent about four hours over three days doing this. The second one only took three hours. If you have any questions on your install, please do not hesitate to ask! I have done these on a few other cars.

Other things could be added, like on/off switches, dimmers, things like that. To be clear, this car has the lights on as long as the track has power. A switch or a DCC decoder could control that, but I didn't really want or need one.

And now for the random pic of the day!

This is one of the new GE ET44AC locomotives. These are the first locomotives to be EPA Tier IV compliant, and certainly distinct. This GECX 2032 is one of the test bed engines that the Class I's have been running. Here it is on a BNSF train being led by a Citirail ES44AC. I caught this engine on the way home from work. It was fun to come across such a rare locomotive without anyone else seeing it!

Nice! I hope you'll be bringing this when you come up for Open House next week!

ReplyDeleteI've done something similar for caboose lighting, the main difference being that instead of using a resistor I used a LM317 voltage regulator with resistors to set the voltage (1.5v for bulbs or ~3v for LEDs). the main reason I chose the voltage regulator is that not all DCC systems use exactly the same voltage for track power, and if one is a few volts higher the resistor will cause a difference in brightness when moved from one layout to another. The voltage regulator keeps the output voltage constant regardless of the input voltage.

I have to admit i was wondering how you would solve the power pickup issue with those cars...good job on that!

This comment has been removed by the author.

ReplyDeleteNot sure why it posted my comment twice, but I deleted the duplicate. Gotta love computers!

ReplyDeleteI just finished installing lights in my San Francisco Chief using a variation of your circuit. The main difference is that I added a 100 ohm resistor between the positive lead of the capacitor and the positive lead of the rectifier. For your purposes (three cars, as I recall) it wouldn't be a problem without it, but for my 10+ car train (a couple of which used multiple strips of LEDs) the inrush current for all those capacitors might have been seen as a short by the DCC system. Adding the resistor limits the inrush current. The 4.7K resistor turned out to be perfect to match my cars to the pre-lit car from Walthers. Now I just need a set of cooks and some dinner plates of food for the dining car to be "finished" with the project.

ReplyDeleteThat is a good idea Robert! I hadn't thought of that, but it is something to consider in any future builds. Maybe an Amtrak or something. Your eye for details and decorated interiors is superb so I know you find the best little cookers and diners haha! I expect to see your whole set soon! Don't be afraid to send pictures of the work!

DeleteYou can count on seeing pictures!

DeleteI already have diners in place, but haven't been able to acquire a set of cooks as of yet.